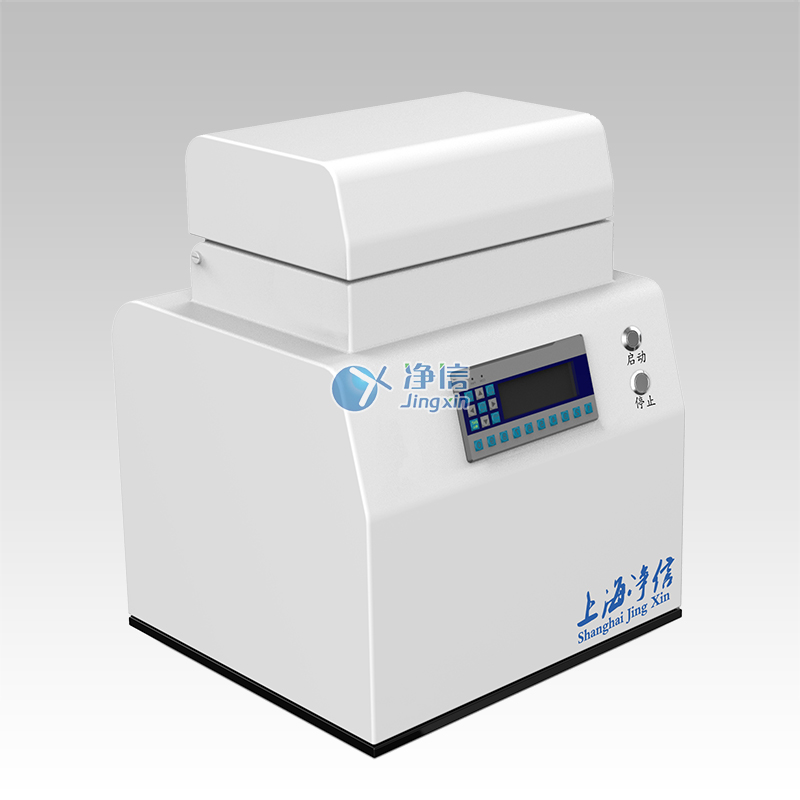

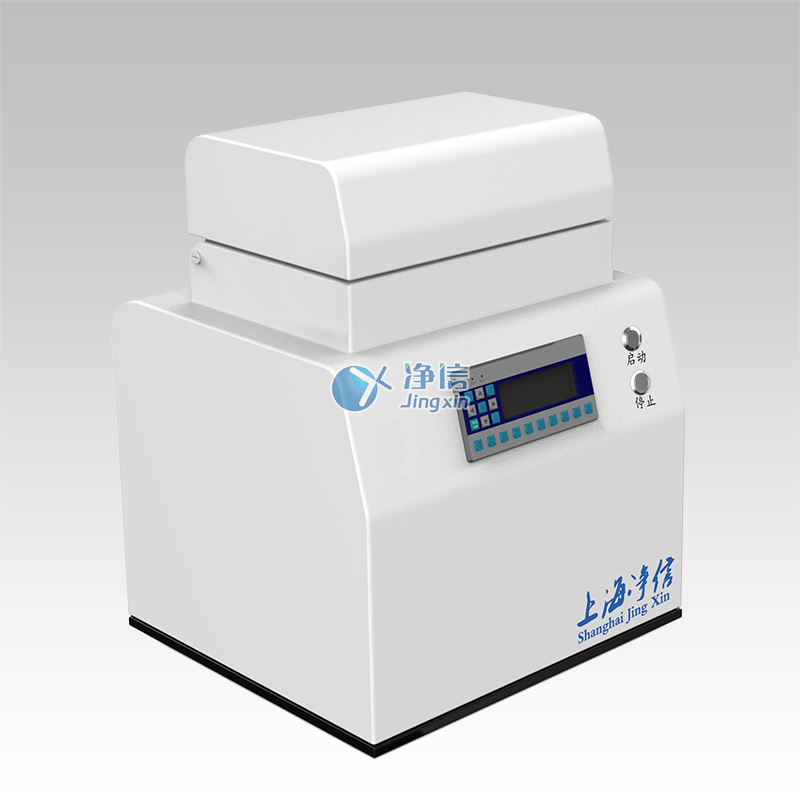

High-energy ball mill JXFSTPRP-GN (patented product, counterfeiting must be investigated! 201620363493X)

Features:

The running process uses the combination of friction and collision force to quickly grind and break the sample in a short time.

Equipped with a cooling system to avoid the heat generated by the high-speed grinding process from affecting the sample.

Can grind medium-hard, hard, brittle, fibrous, dry or wet samples.

The special geometric design of the grinding jar allows the samples to be fully mixed and the grinding results are highly uniform.

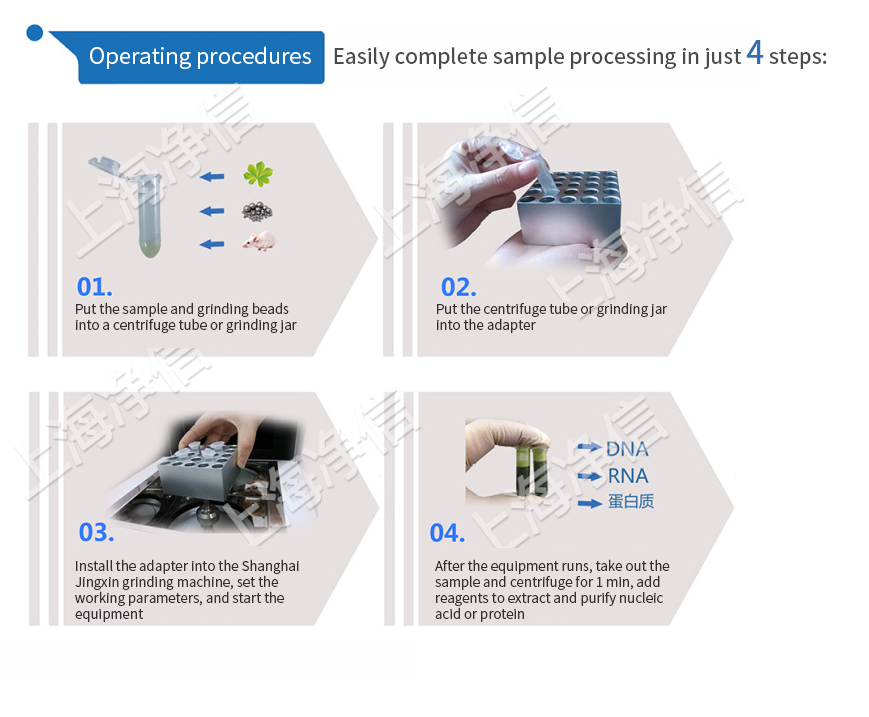

Operating procedures:

The main parameters | Parameter range |

Injection size: | < 5 mm |

Sample size: | < 80 nm |

Processing sample size: | 24x 2ml 4x 15ml 2x 50ml |

Grinding jar material: | The instrument can be configured with grinding jars made of stainless steel, tungsten carbide, and zirconia. Grinding jar with complete safety fastening |

Number of grinding platforms: | >2 |

Noise level: | <55db |

Rotating speed: | 300 – 2000 rpm, continuously adjustable |

Temperature control: | Configurable operating temperature in grinding programs, including higher and higher operating temperatures |

Grinding Ball Material: | Stainless Steel Chrome Steel Zirconia Tungsten Carbide Quartz Sand |

Cooling system : | Liquid nitrogen refrigeration system (external cooling device, optional) can save cooling intermittent time and realize uninterrupted grinding. |

Operational Safety: | The position of the grinding jar is automatically monitored, and if the placement is not standardized, the experiment cannot be performed. The system monitors the imbalance condition in real time. If the imbalance exceeds the controllable range, the equipment will automatically stop running. The remaining operating time is displayed, and the task can be restarted at any time once the balance is restored. |

Reversible intermittent drive: | Touch screen control, easy to operate, save at least 10 sets of programs. |

Experimental site: