Model:JXHY-5L

Brand:Shanghai Jingxin

Specifications :Set

Introduction:Driven by the drive shaft, the loaded cylinder will make repeated translational, rotating and rolling motions of materials of different specific gravity, which will force the materials to move along the cylinder in the three directions ......

Product Description:

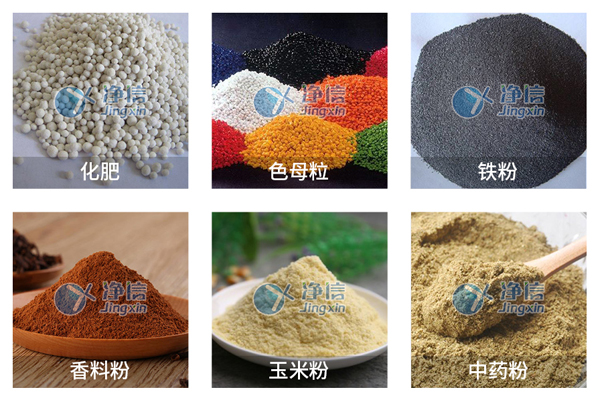

The three-dimensional mixer is mainly used to mix different types, different particle sizes, and high-uniformity mixing materials. It is suitable for soft, medium-hard, brittle and fiber material samples, and is widely used in various industries and daily life. The sample is mixed in a completely closed container, which can achieve dry-dry sample mixing, dry-wet sample mixing, and wet-wet sample mixing. Uniform mixing guarantees credible analysis results and is an ideal choice for quality control and research and development.

working principle:

Driven by the drive shaft, the loaded cylinder will make repeated translational, rotating, and tumbling motions of materials with different specific gravities, so as to encourage the materials to perform circular, radial, and axial three-way compound movements along the cylinder. So as to realize the mutual flow, diffusion, accumulation and doping of various materials, and achieve the purpose of uniform mixing. The whole process ensures that it is dust-free and easy to clean.

Features:

1. The material has no centrifugal force, no specific gravity segregation, stratification, and accumulation. Each component can have a large disparity in weight ratio, and the mixing rate is high. It is an ideal product in various mixers at present.

2. Large charging rate, high efficiency and short mixing time.

3. All parts of the cylinder are arc-transitioned and precision polished. There are no dead corners, no pollution, safe discharge, simple cleaning and easy operation, etc.

4. Low vibration, low noise, freely adjustable working position, convenient installation and maintenance, and long service life

5. Due to the multi-directional movement of the mixing barrel, there are many mixing points for the material in the barrel, and the mixing effect is remarkable. The uniformity of the mixing is higher than that of the general mixer, and the uniformity error of the drug content is lower than that of the general mixing. machine.

6. The materials are mixed in a closed state, which will not pollute the working environment;

7. Low height and small rotation space.

Application range: It is suitable for high uniformity mixing of powder and granular materials in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, national defense industry and various scientific research units.

Product parameters:

Main parameters | Parameter range | ||

Model | JXHY-2L | JXHY-5L | JXHY-10L |

Dimensions (mm): | 560*490*340 | 720*650*950 | 850*700*1050 |

Instrument weight: | 50kg | 150kg | 180kg |

Working speed: | 0-120 rpm | 0-24 rpm | 0-24 rpm |

Test tube specifications: | 2L | / | / |

rated power: | 300W | 550W | 550W |

power supply: | 220 V 50Hz | / | / |

Loading dissolution volume (L) | / | 4 | 8 |

Loading weight: | / | 2.5kg | 5kg |

Hopper capacity: | 2L | 5L | 10L |

Effect picture: